Material Testing

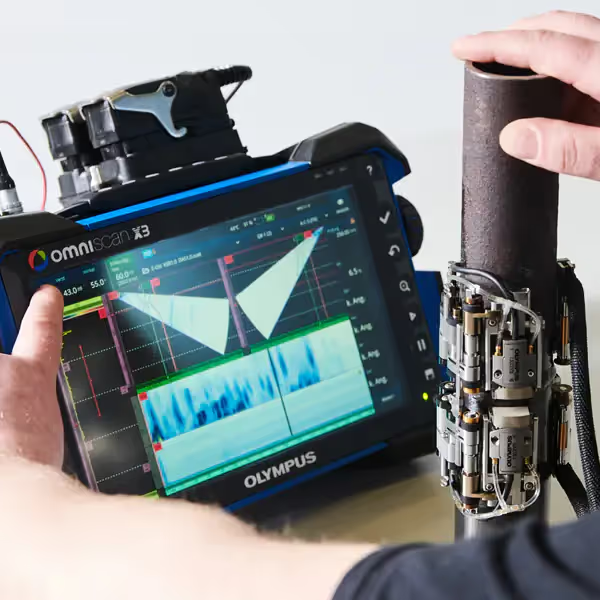

Generic term for non-destructive (NDT) and destructive testing methods (DT) for quality assurance. Competent, precise, and reliable.

Learn More- Non-destructive & destructive testing methods

- Quality assurance and component approval

- For industry, manufacturing & production