What is Surface Crack Testing (OFR)?

Surface crack testing, also known as Oberflächenrissprüfung (OFR), is an essential non-destructive testing (NDT) method for detecting cracks and other discontinuities that are open to the surface of components. This ensures the integrity and safety of parts in critical applications—ranging from industrial manufacturing and metal construction to safety-relevant machine components.

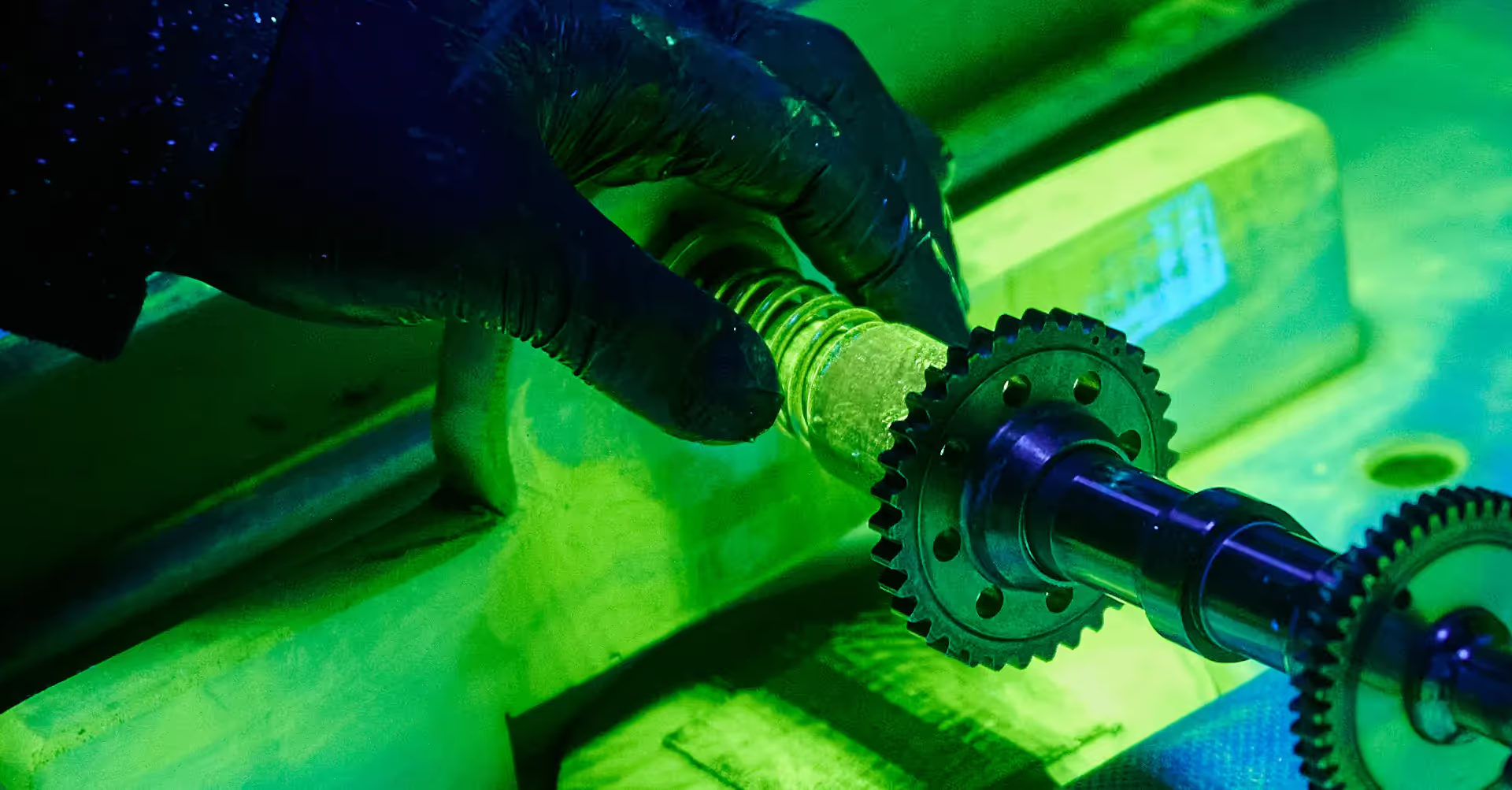

At Zeros GmbH, our accredited laboratory and mobile testing teams utilize two highly effective methods for surface crack detection: Penetrant Testing (PT) and Magnetic Particle Testing (MT). Both methods allow for the reliable detection of surface-breaking cracks, laps, seams, and porosity in a wide range of materials—without damaging the component.

Penetrant Testing (PT): The Color Penetrant Method

Penetrant Testing (PT) is suitable for non-porous materials such as metals, ceramics, and some plastics. The process involves applying a liquid penetrant to the clean surface of the component. This penetrant seeps into any open surface defects by capillary action. After a suitable dwell time, the excess penetrant is carefully removed, and a developer is applied. The developer draws the penetrant out of the defects, making even the finest cracks visible under appropriate lighting conditions.

- Ideal for detecting very fine, surface-breaking cracks

- No influence on the component properties

- Applicable to a wide range of materials

Magnetic Particle Testing (MT): The Magnetic Powder Method

Magnetic Particle Testing (MT) is used for ferromagnetic materials such as steel and iron. The component is magnetized, and a fine magnetic powder (dry or suspended in liquid) is applied. Cracks and other discontinuities at or near the surface interrupt the magnetic field, causing the particles to gather at these locations and form visible indications. This method is highly sensitive and fast, making it ideal for on-site inspections of welds, castings, and forged parts.

- Fast, reliable detection of surface and near-surface cracks

- Especially suitable for weld seam and component testing in steel construction

- Immediate visual results, also outdoors or on large structures

Our Testing Process: Step by Step

-

Preparation: The component surface is thoroughly cleaned to remove oil, grease, dirt, and other contaminants. This ensures reliable test results.

-

Application of Test Medium: Depending on the selected method (PT or MT), either a penetrant or magnetic particles are applied to the component.

-

Dwell and Development: The test medium is allowed to act for a defined time. With PT, a developer is subsequently applied.

-

Evaluation: The surface is visually inspected under suitable lighting (white or UV light), and any defects are clearly marked and documented.

-

Documentation: All results are recorded in a digital or written test report, including photographic evidence if desired.

Advantages of Crack Testing with Zeros GmbH

- Certified laboratory (DIN EN ISO/IEC 17025) and experienced, qualified inspectors

- On-site testing service for large or installed components

- Fast response times and flexible scheduling

- Clear, traceable documentation and consulting for optimal testing strategy

“Exact defect detection – where it matters.”

Typical Applications

- Industrial components, castings, and forgings

- Weld seam inspection in steel construction and pipeline construction

- Machine housings and safety-critical parts

- Quality assurance in manufacturing and repair

- Acceptance and periodic inspections according to standards

Why Choose Zeros GmbH?

Whether you need a one-time inspection or regular quality assurance, Zeros GmbH is your reliable partner for non-destructive surface crack testing. Our team combines technical know-how, state-of-the-art equipment, and a commitment to precision and safety. We offer both laboratory testing in Berlin and flexible on-site inspections throughout Germany.

Contact us today for a tailored solution and a non-binding quote. We will be happy to advise you on the right method and the best procedure for your application.