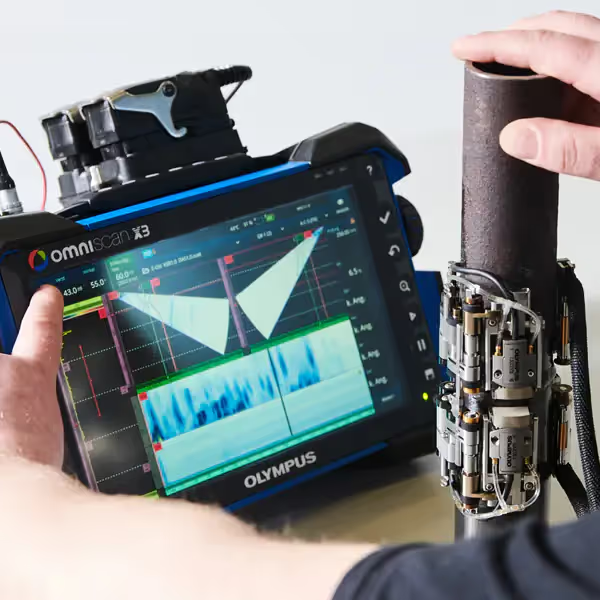

Technical Execution of Wall Thickness Measurement with Ultrasonic Testing (UT)

In wall thickness measurement with ultrasound, a short sound pulse is coupled into the component with a probe. The pulse propagates through the material at a material-specific sound velocity, is reflected at the back wall, and received again as an echo by the probe. From the measured time between the transmitted and received signal and the known sound velocity in the material, the device calculates the exact wall thickness:

Wall Thickness = (Sound Velocity × Time) / 2

For the calculation, the material-specific sound velocity is required (see table below). Each material has a characteristic sound velocity that must be known for precise measurement results.

Ultrasonic Testing enables wall thickness measurements in a range from about 1 mm up to several hundred millimeters – depending on material and probe. Both contact technique (with coupling medium, e.g. for steel pipes, sheets) and immersion technique (e.g. for small or complex components) are used.

- Precise and repeatable measurement values

- Non-destructive testing – no impairment of the component

- Fast, mobile, and also applicable in hard-to-reach places

Different Materials

| Material | Longitudinal Wave | Transversal Wave |

|---|---|---|

| Water | 1.48 km/s | – |

| Lead | 2.16 km/s | 0.70 km/s |

| Plexiglass | 2.73 km/s | 1.36 km/s |

| Brass | 4.70 km/s | 2.10 km/s |

| Gray Cast Iron | 3.50 km/s | 1.90 km/s |

| Copper | 4.70 km/s | 2.26 km/s |

| Steel | 5.90 km/s | 3.20 km/s |

| Titanium | 6.10 km/s | 3.10 km/s |

| Aluminum | 6.40 km/s | 3.10 km/s |