Procedure Qualification & Welder Qualification

NDT & Maintenance Worldwide – Reliable & Certified

Request Now- Over 25 years of experience in procedure and welder qualification

- UT, MT, PT, VT & Phased Array

- Mobile inspections worldwide

NDT & Maintenance Worldwide – Reliable & Certified

Request NowProcedure & Welder Qualification

Zeros GmbH has been a reliable partner for over 25 years in procedure and welder qualifications and non-destructive testing (NDT) worldwide. Using state-of-the-art testing technology and internationally trained specialists, we ensure maximum safety and availability of your equipment.

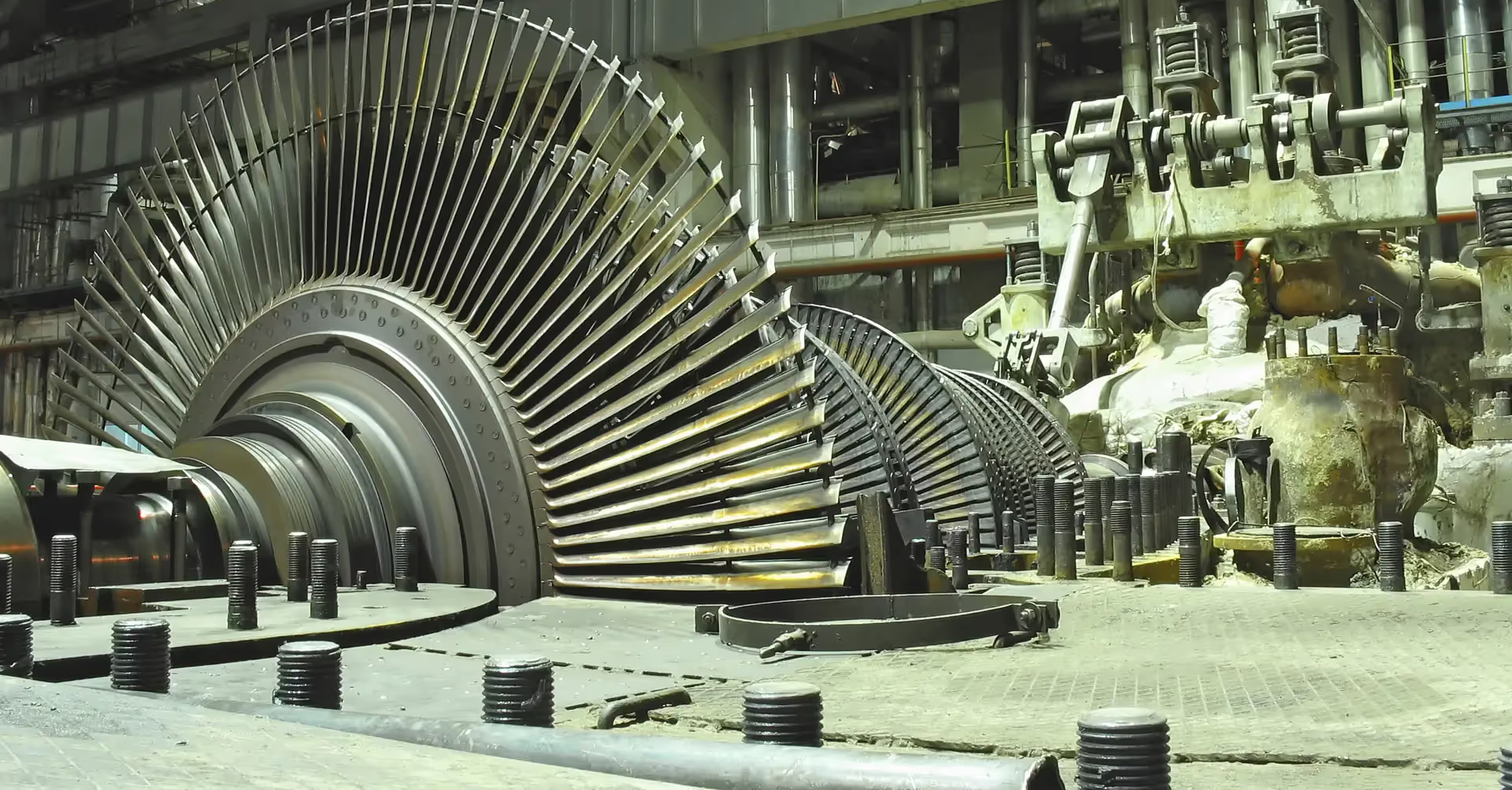

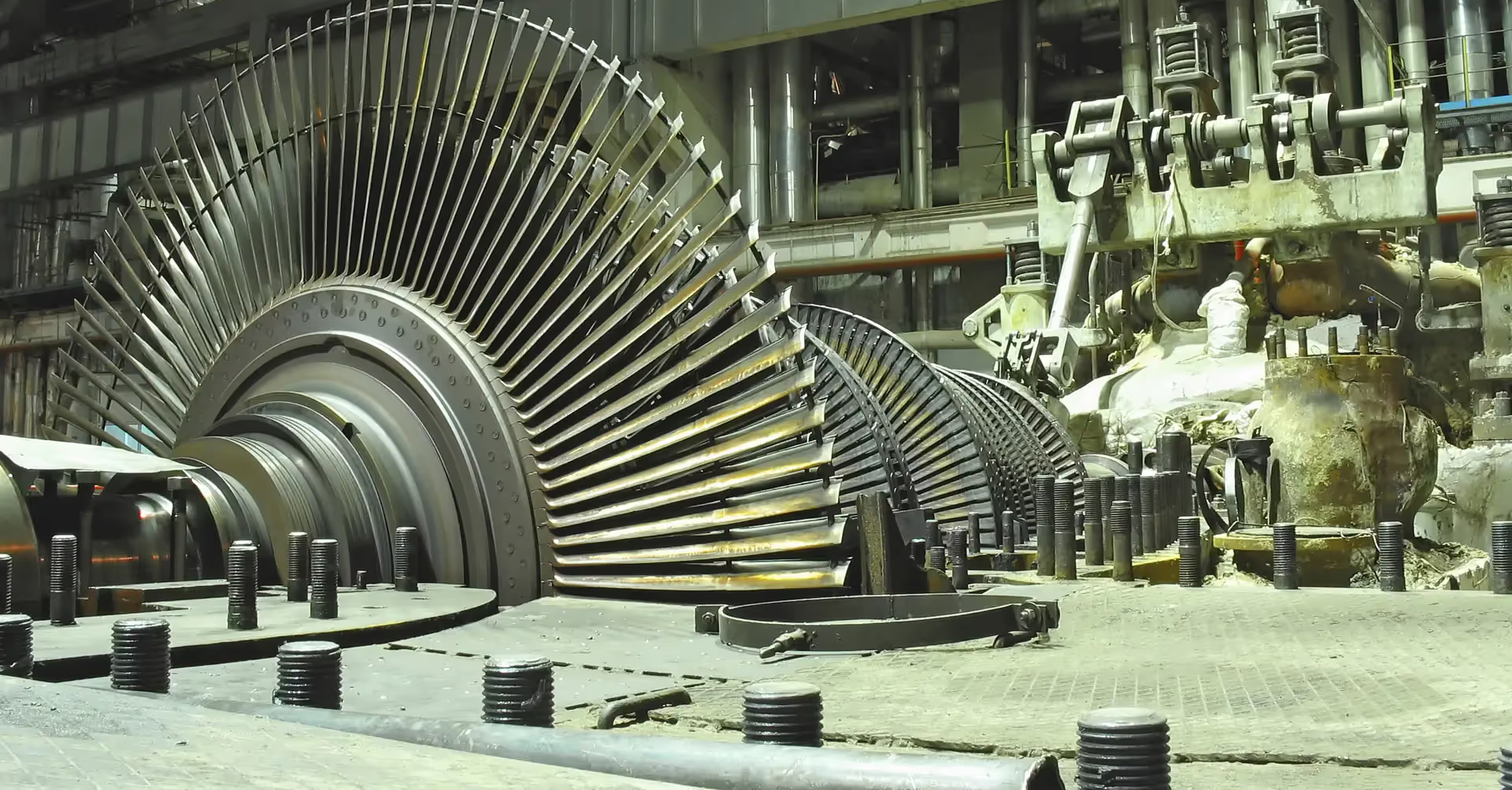

Qualification of a 12.5 MW steam turbo unit with UT and PT testing on valves, bearings, gear tooth volume inspections, as well as MT testing on turbine housings and blades.

Regular procedure and welder qualification is essential for operators to ensure operational safety, avoid unplanned downtime, and detect potential damage early. Our non-destructive testing methods—including ultrasonic testing (UT), magnetic particle testing (MT), dye penetrant testing (PT), visual testing (VT), phased array, and mobile radiographic inspections—guarantee reliable assessment of even complex components.

Inspections cover turbines, rotors, generators, valves, housings, bearings, and blades, ensuring efficiency and longevity of key plant components.

In practice, we recommend qualification every 3 to 5 years, depending on the type of equipment, operating conditions, and operator requirements. Through our global network, we offer these services not only regionally but also internationally—including all logistical and regulatory requirements.

Our NDT Methods

Non-destructive testing worldwide

Zeros GmbH is an independent testing laboratory for destructive and non-destructive materials testing. We support companies from incoming inspection to series release – including digital test reports and full traceability.

We operate under accreditation to DIN EN ISO/IEC 17025 (quality management for laboratories). See our current accreditation information here.

We are accredited by DAkkS to DIN EN ISO/IEC 17025. This standard ensures that test methods, equipment control, personnel qualification and reporting meet the highest requirements.

An overview of services and scopes is available on our homepage.

Our portfolio covers NDT (UT, RT, MT, PT, VT), mechanical testing (tensile, hardness, Charpy), metallography (microstructure, grain size, coating thickness) and chemical analysis (e.g. OES, XRF). We also provide specimen preparation, documentation and consulting.

Please contact us by email or use the contact option on the website. Share material, standard/specification and quantity – we'll get back to you promptly with a solution.