How does TOFD Ultrasonic Testing work?

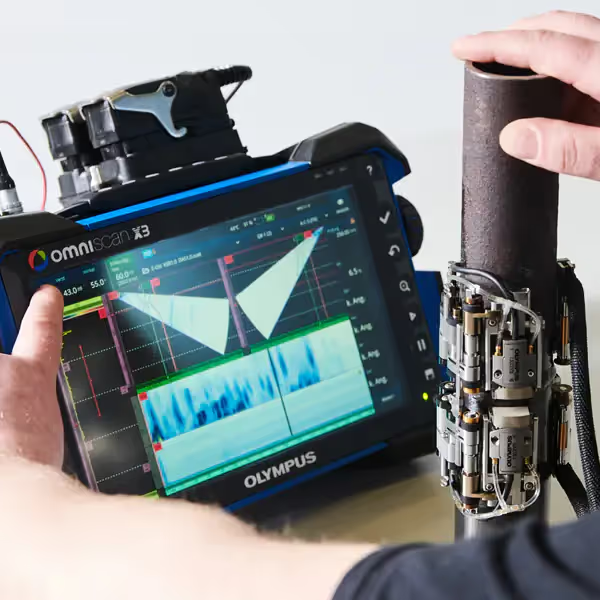

In the TOFD method (Time-of-Flight Diffraction), two ultrasonic probes (transmitter and receiver) are positioned opposite each other on the weld seam. The transmitter emits short pulses through the material, and the receiver records the incoming signals.

Unlike the classical pulse-echo method, TOFD is not based on reflected echoes but on the diffraction of sound waves at the tips of defects, e.g., cracks. By precisely measuring the time differences of these diffracted waves, the exact depth and height of a defect can be calculated.

The result is a time-resolved signal diagram displayed as a grayscale image (B-Scan). This shows the crack tips and the base material as characteristic lines, allowing an experienced inspector to reliably detect and evaluate cracks.

Advantageously, TOFD operates independently of defect orientation, offers high repeatability, and enables comprehensive documentation through digital recording.

The following overview shows the most important signals recorded in TOFD ultrasonic testing and their significance for defect evaluation.

| Signal Type | Origin | Interpretation / Meaning |

|---|---|---|

| Lateral Wave | Direct path along the surface between transmitter and receiver | Reference signal – used for time calibration |

| Upper Diffracted Wave | Diffraction at the upper tip of a crack | Upper crack start visible in the B-Scan |

| Lower Diffracted Wave | Diffraction at the lower tip of a crack | Lower crack end, enables depth determination |

| Back Wall Echo | Reflection from the opposite component surface | Shows material thickness, possibly shadowed by defects |